How to Analyze Nylon Fabric Material Using Burn Test Method

2023-04-07 | Production and testing of fabrics

Nylon fabric is a popular material used in a variety of clothing and textile products. It is known for its durability, strength, and resistance to wear and tear. However, it is important to know how to properly identify and analyze nylon fabric to ensure its authenticity and quality. One effective method to analyze nylon fabric is through the burn test.

The burn test is a simple and effective way to determine the fiber content of a fabric. Here are the steps to perform a burn test on nylon fabric:

Step 1: Prepare the Fabric Sample

Take a small sample of the nylon fabric, about 1 inch in length, and remove any loose threads. It is recommended to use a fabric sample that is not visibly damaged or stained.

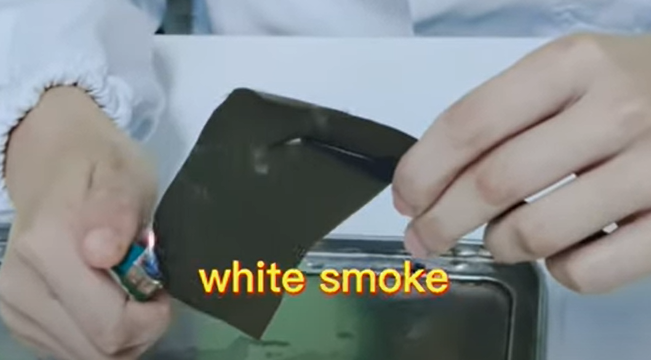

Step 2: Ignite the Fabric

Use a lighter or a match to ignite the fabric sample. Hold the fabric with a pair of tweezers or a metal clamp to prevent burning yourself.

Step 3: Observe the Flame

Observe the flame and the smoke produced by the burning fabric. Nylon fabric will melt and shrink away from the flame. It will produce a blue flame and will continue to burn after the flame is removed. Nylon also produces a strong, unpleasant odor similar to burning plastic.

Step 4: Examine the Ash

After the fabric has burned, examine the remaining ash. Nylon fabric will leave a hard, bead-like ash that is difficult to crush. The ash will be a light gray or white color.

It is important to note that nylon fabric can be blended with other synthetic or natural fibers, which can affect the results of the burn test. Therefore, it is recommended to perform the burn test on multiple areas of the fabric sample to ensure accuracy.

In conclusion, the burn test is a simple and effective way to analyze the material of nylon fabric. By following these steps, you can easily determine if the fabric is made of nylon and ensure its quality and authenticity.

If you want to know other information,please click it:https://www.youtube.com/@szitextile

Related News

Exploring the Versatility and Durability of Nylon 1000D Fabric

Nylon 1000D fabric is a versatile and durable textile that has found a wide range of applications across various industries. This high-performance fabric is known for its exceptional strength, resistance to wear and tear, and versatility, making it a popular choice for a wide range of products. In this article, we will explore the features, benefits, and applications of nylon 1000D fabric.

5 Ways Military Fabric Makes Your Life More Secure

Military fabrics are made for different purposes and are very versatile but the main purpose of those fabrics is to protect the owner from external threats. Here are 5 lifesaving abilities of military fabric.